Inert Atmosphere Systems

Containment made easy: Gloveboxes for sensitive environments & hazardous materials… !!!!

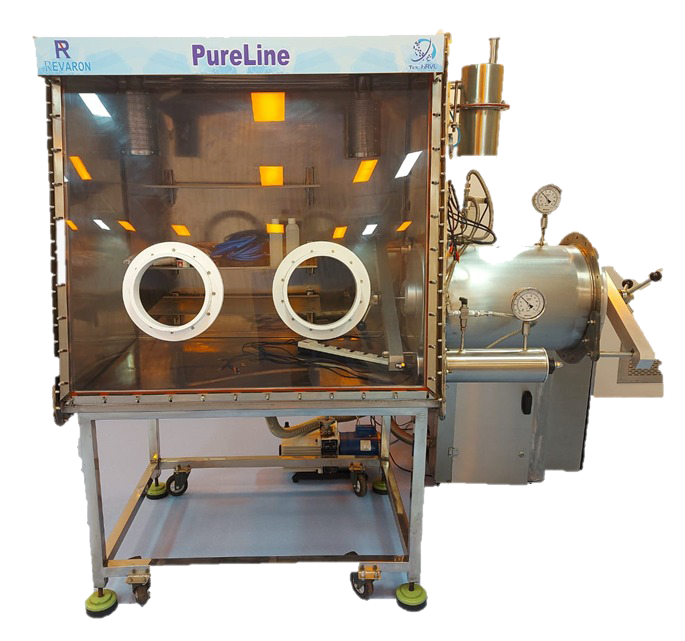

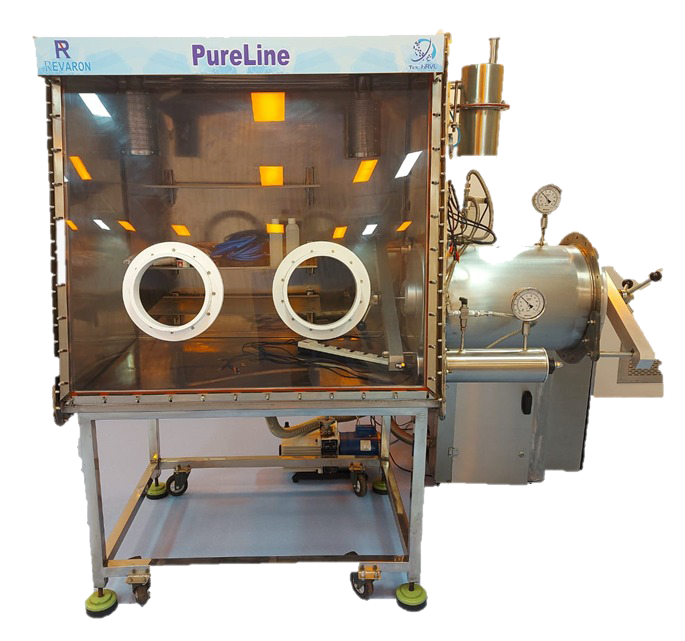

We are a leading glovebox manufacturer, specializing in the design and production of high-quality gloveboxes for a variety of industries. Our gloveboxes are used in research and development labs, pharmaceutical and biotech companies, additive manufacturing companies and other industries where controlled environments are essential for conducting experiments or handling hazardous materials. We have expertise and experience in the industry and have built a reputation for producing reliable and durable gloveboxes that meet the strictest quality standards. Our team of experts is dedicated to providing the best possible solutions for your specific needs and requirements.

Thank you for considering us as your glovebox manufacturer. Please don't hesitate to contact us if you have any questions or would like to discuss your specific needs. If your glove box requirement is not covered here it does not mean we are not interested, we look forward to assisting you with any glove box design, technology and problem.

Reviun Ltd, the United Kingdom's leading specialist in the design, manufacture and trade of inert gas glove boxes, containment and gas purification systems, for research and industry.

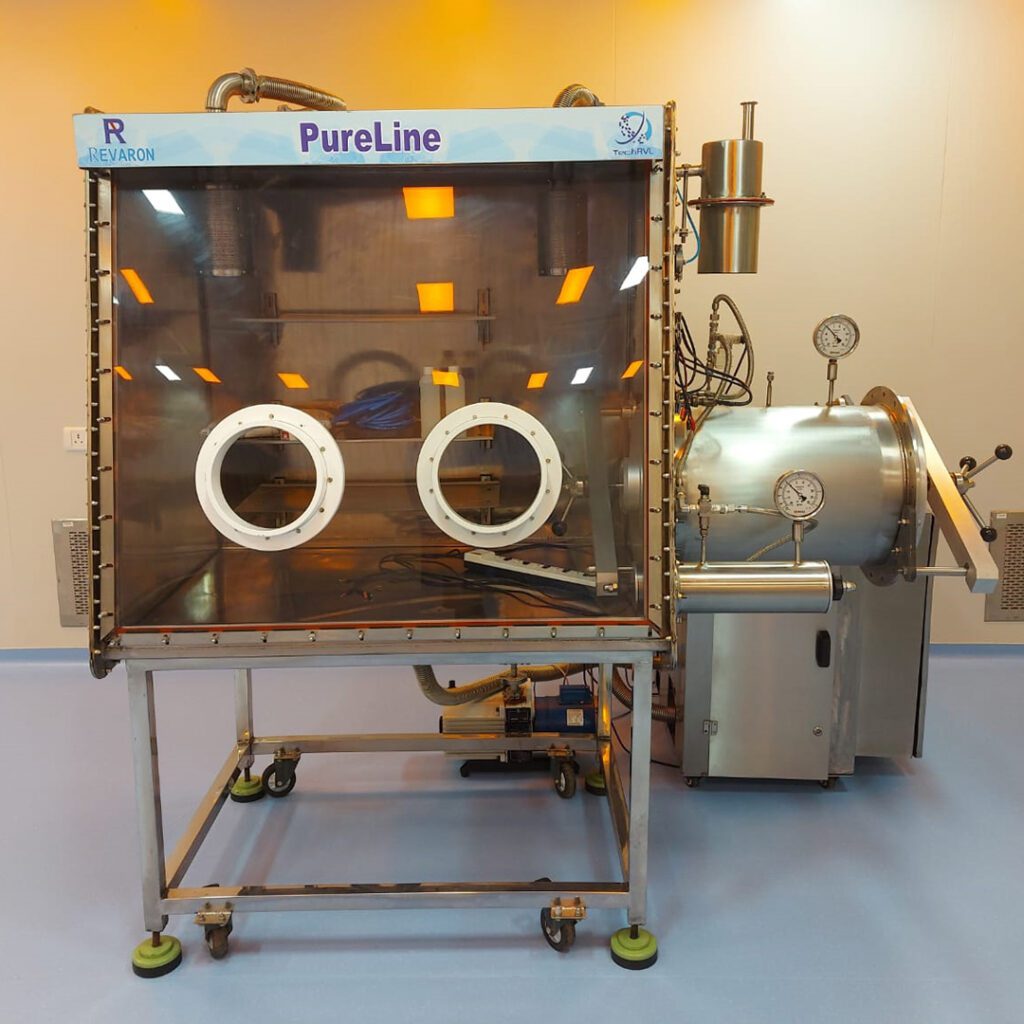

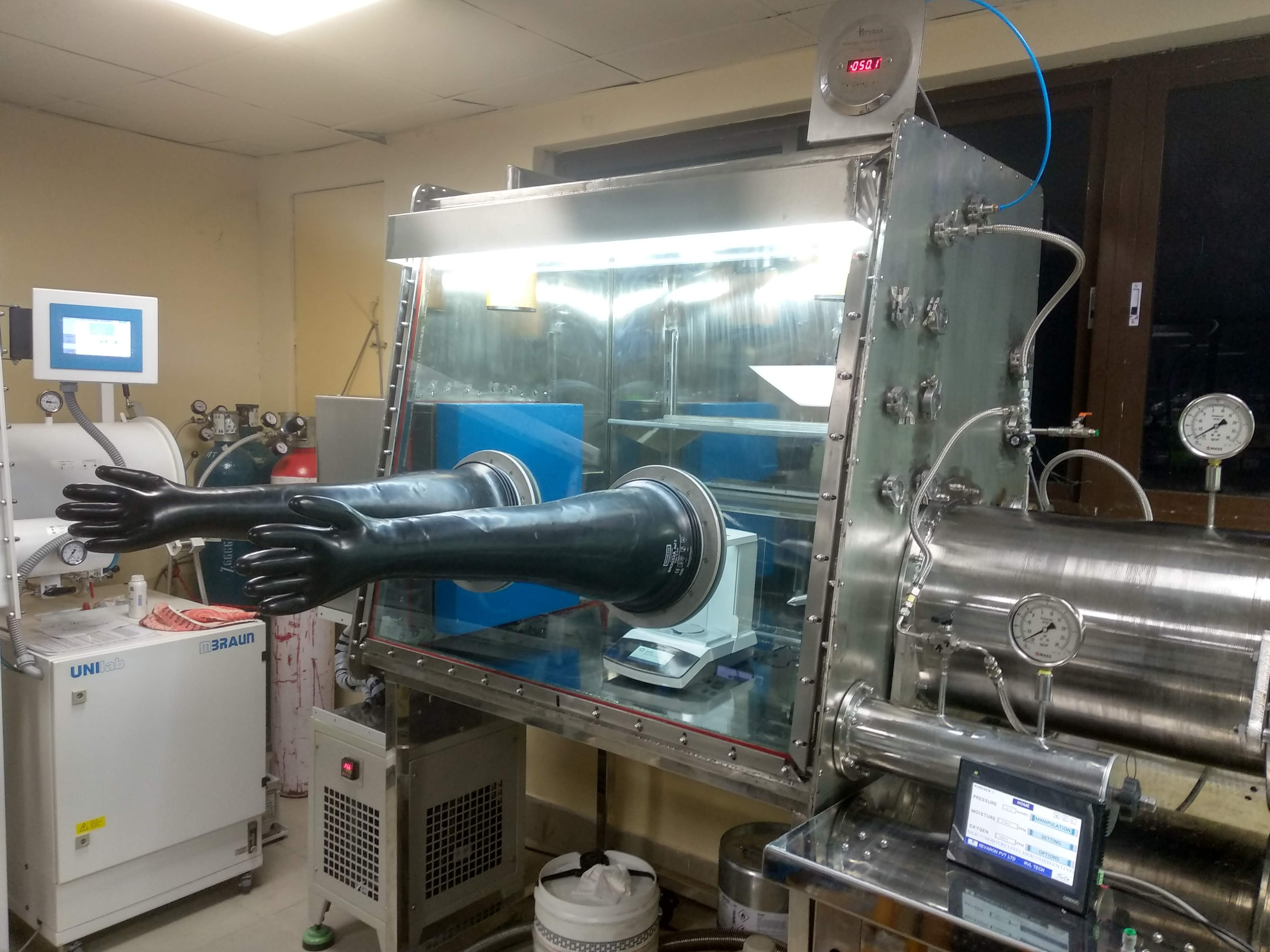

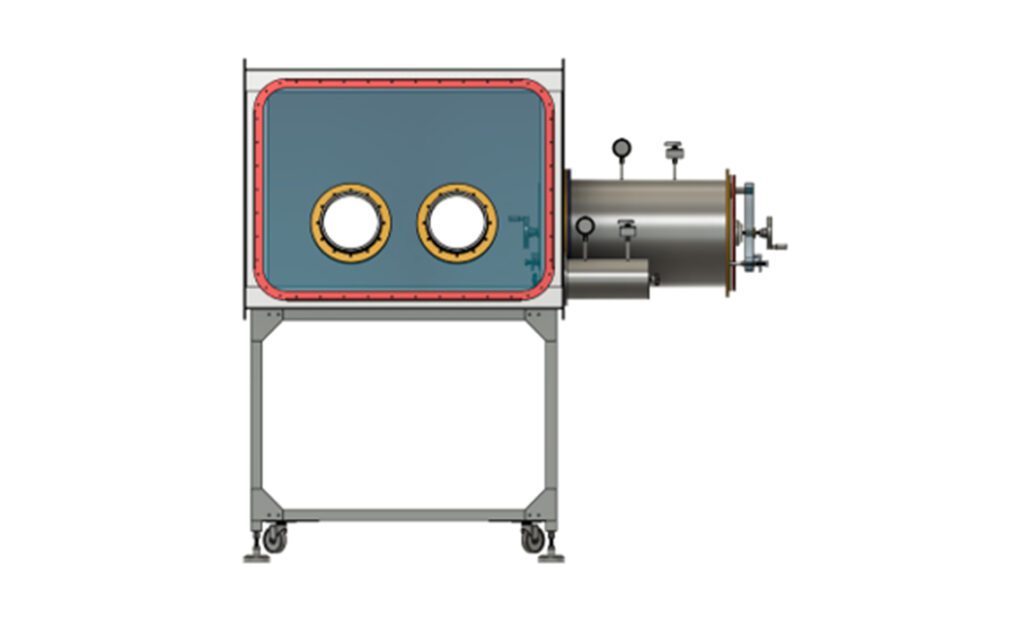

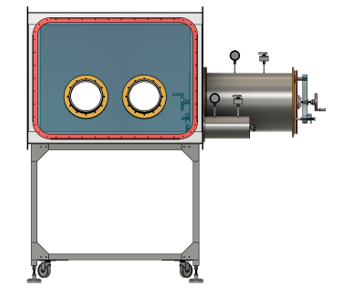

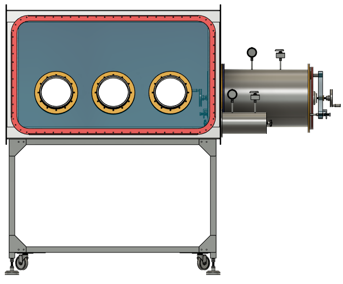

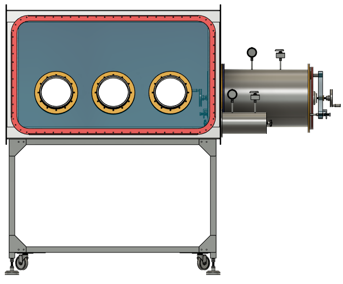

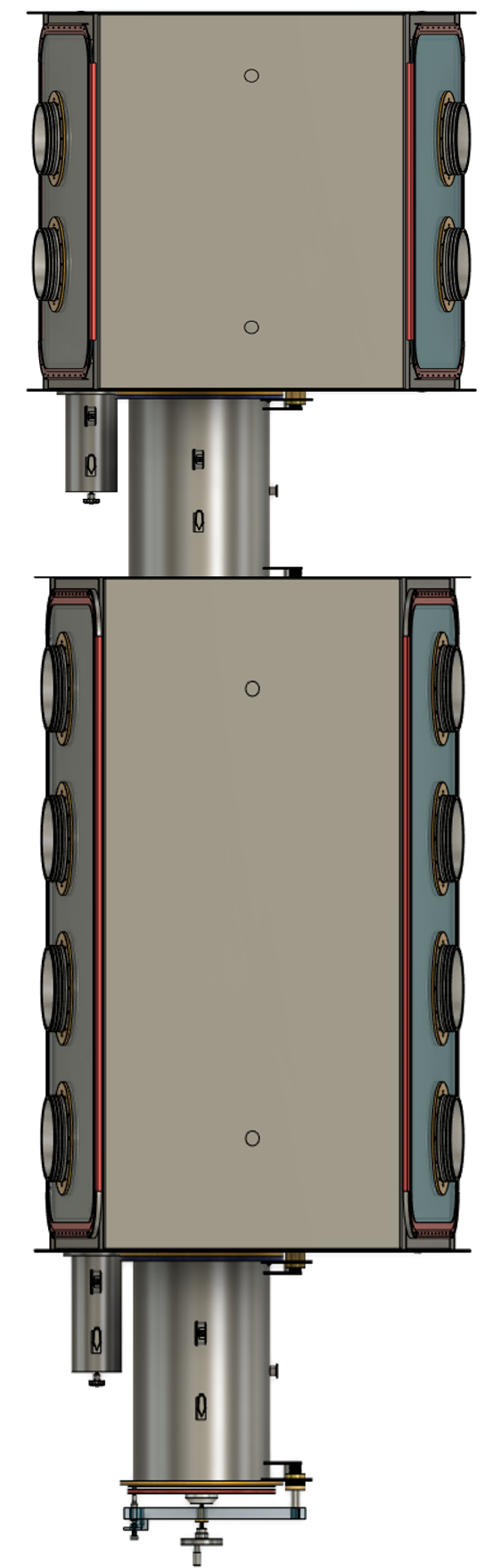

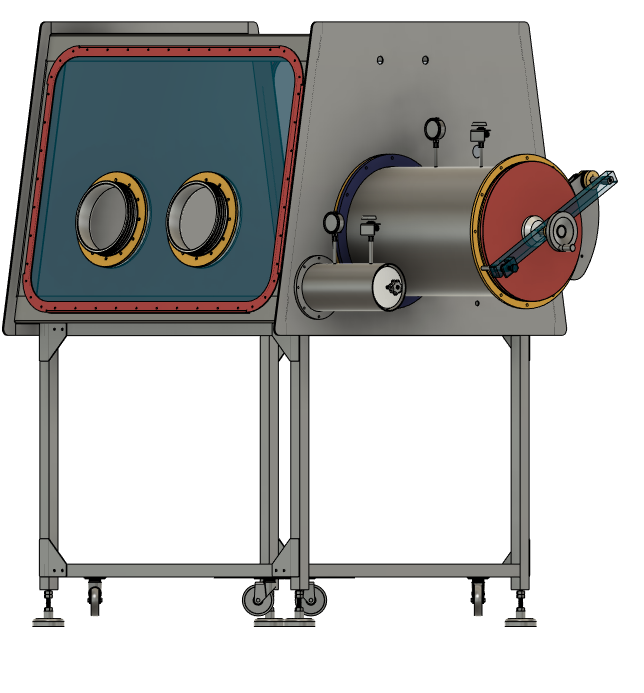

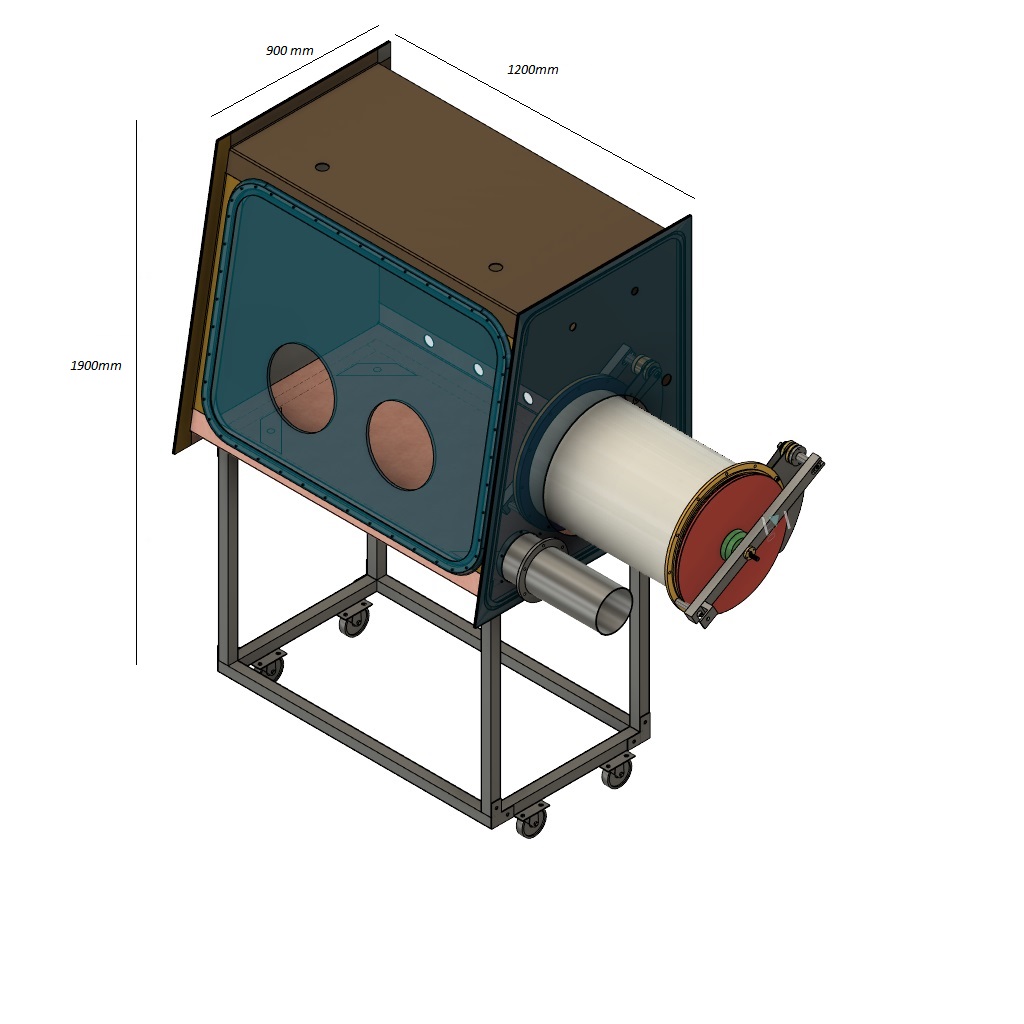

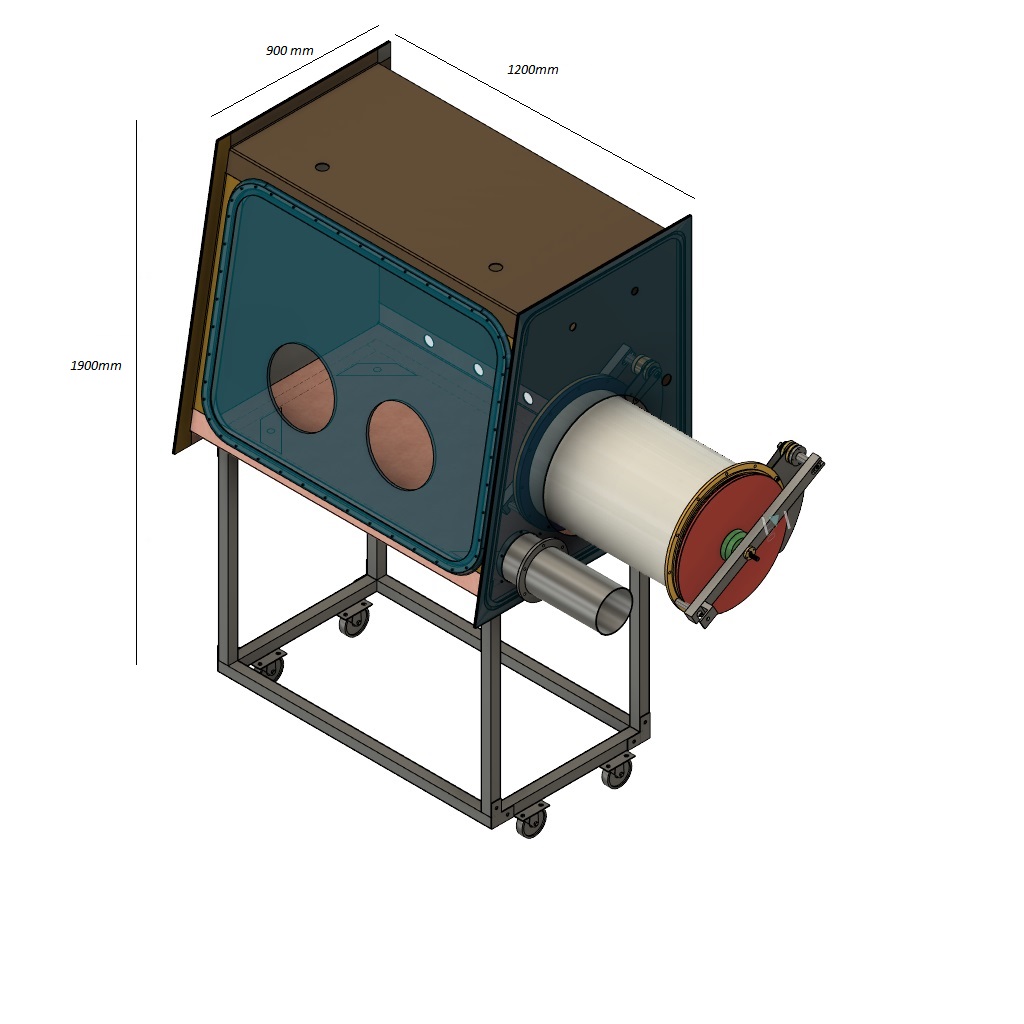

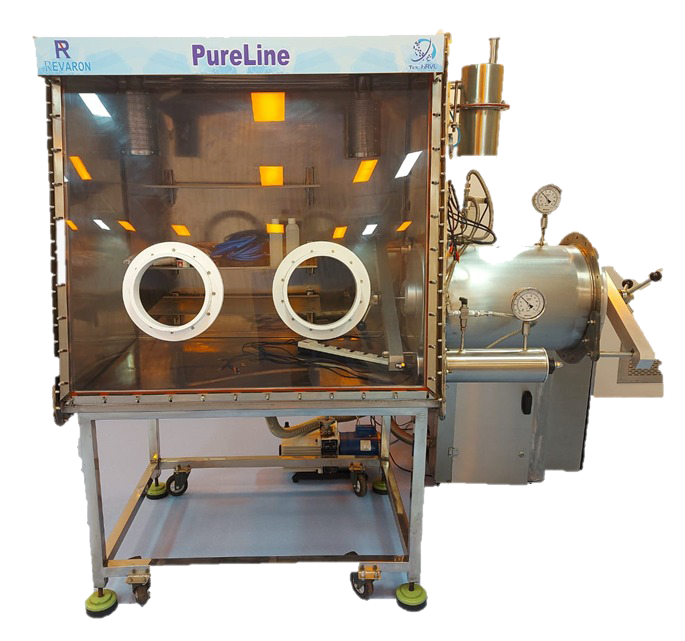

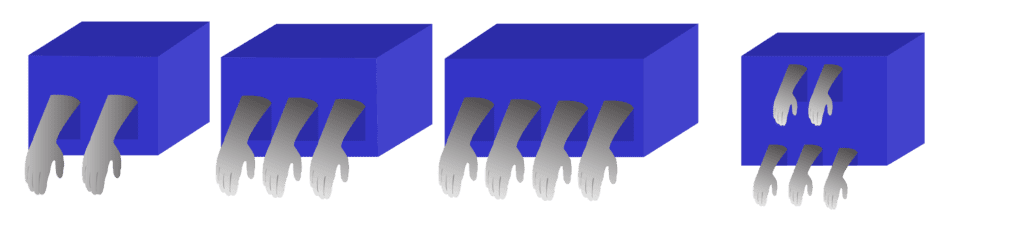

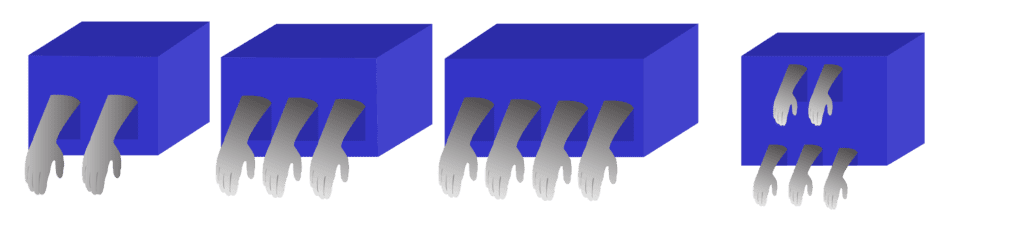

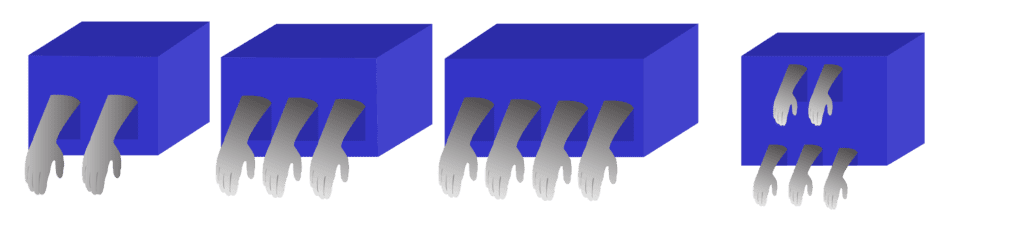

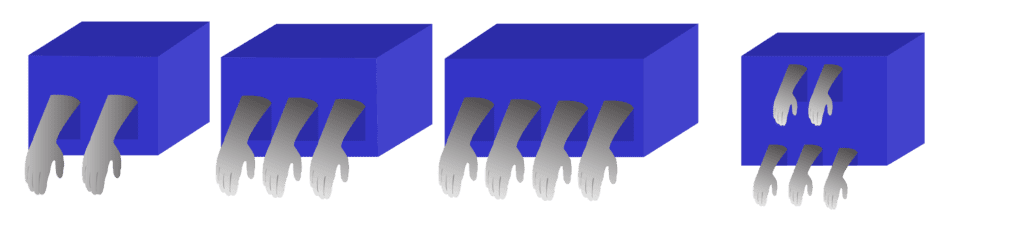

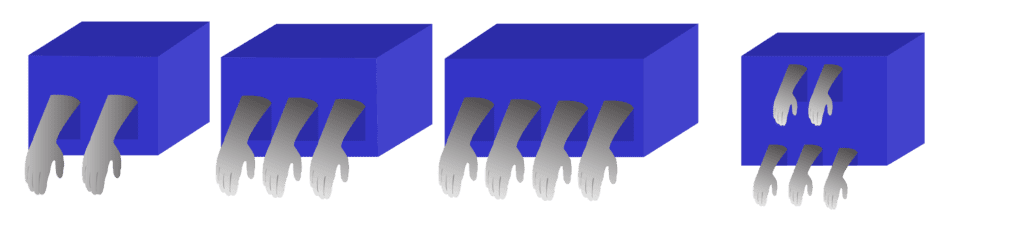

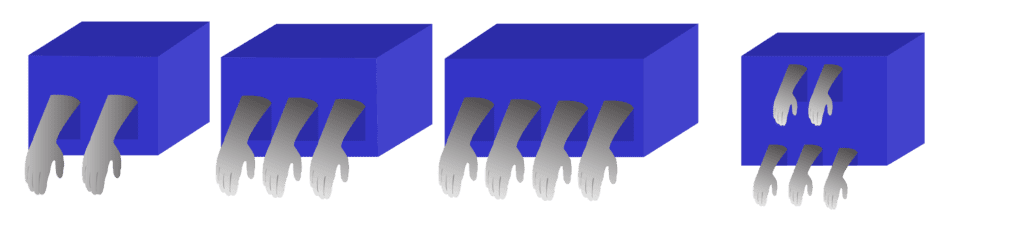

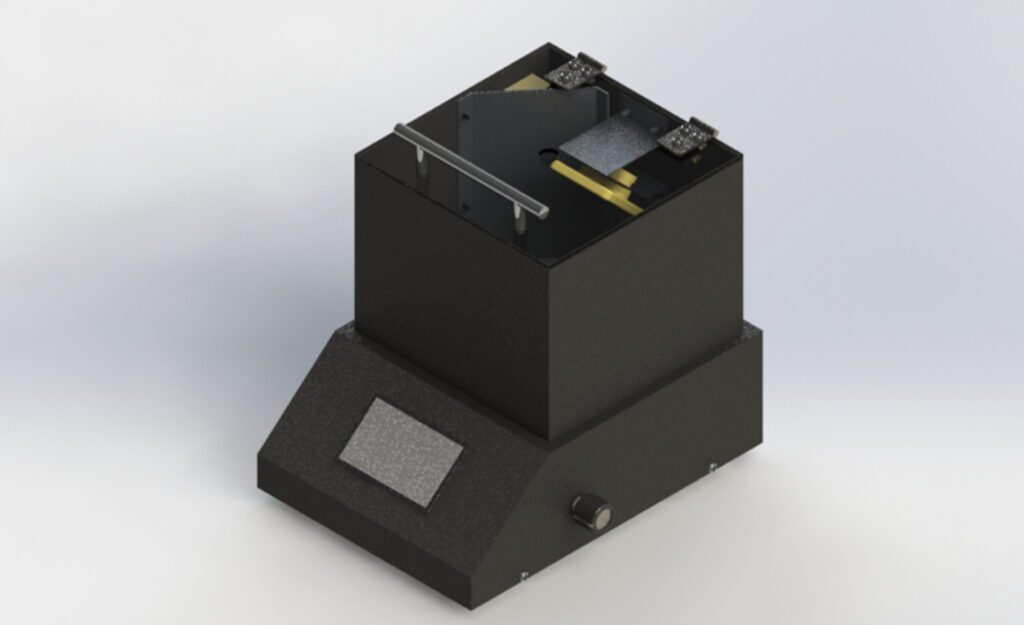

A Glovebox Is A Type Of Enclosed Workspace That Allows Users To Manufacture Or Conduct Experiments In A Controlled Environment. Our Standard Gloveboxes Are Designed To Meet The Needs Of A Wide Range Of Industries And Applications. They Are Constructed Using High-Quality Materials And Are Designed To Be Durable And Reliable. Our Standard Gloveboxes Come Equipped With Everything You Need To Get Started, Including Gloves, A Light, Purification System, Regeneration Unit, Antechambers, Control System, Sensors, And Various Standard Accessories And Parts. They Are Easy To Use And Maintain, And Our Team Of Experienced Technicians Are Available To Provide Ongoing Support And Service.

One Year Warranty

Installation And Training Within One Day

Two Year Limited Warranty

Conform To CE

GBII

GBIII

GBIV

GBSingle-Side

GBDouble-Side

GBCascaded

GBArgon

GBNitro

GBDry-box

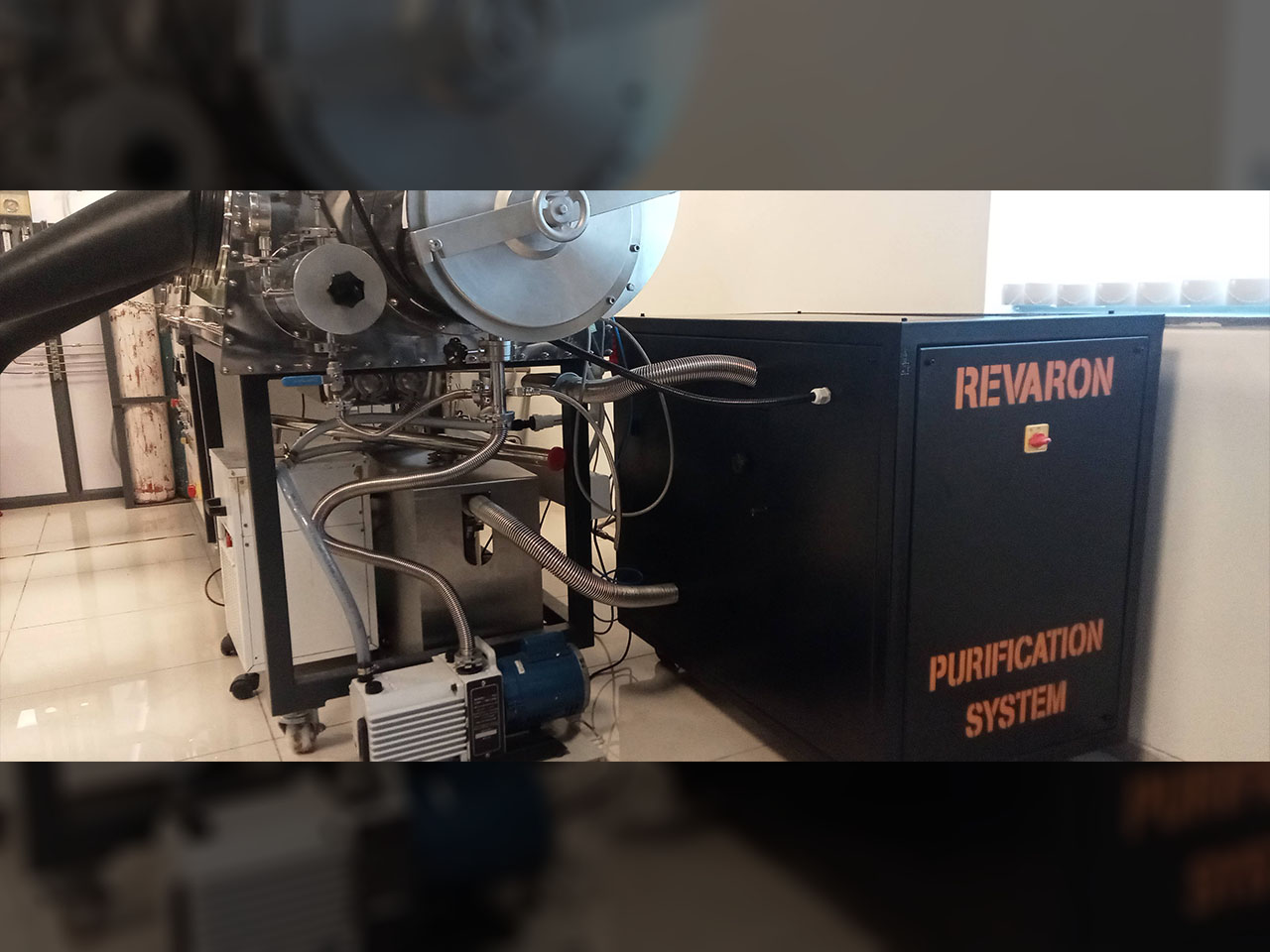

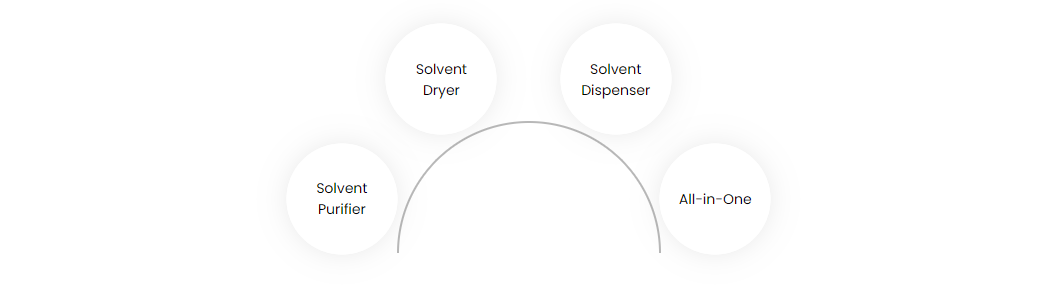

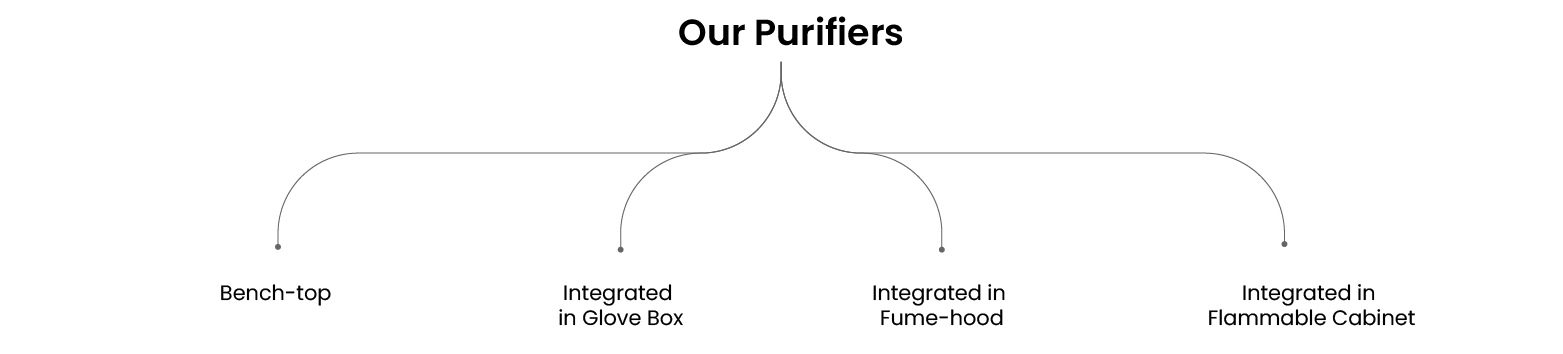

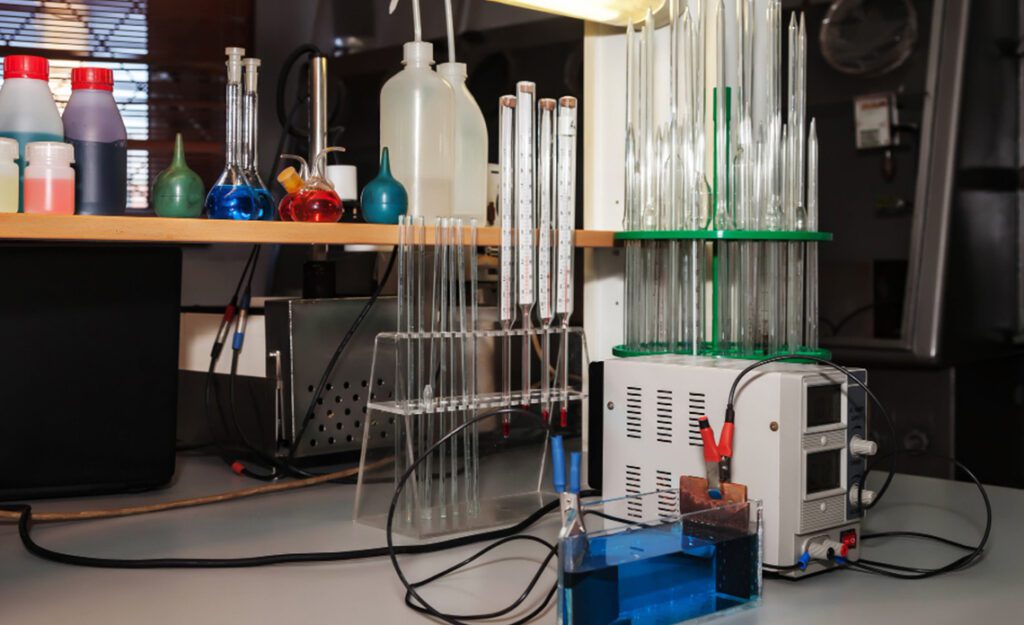

Are You Looking To Ensure The Purity And Quality Of The Gases And Solvents Used In Your Glovebox? Look No Further!

Gloveboxes are used in a variety of industries, including research and development labs, where controlled environments are essential for conducting experiments, manufacturing or handling hazardous materials. These environments often require the use of gases and solvents, which can be contaminated by the moisture, oxygen and air.

Our company has developed high-quality realiable purification services to ensure that the gases and solvents used in the glovebox are pure and uncontaminated. We use state-of-the-art equipment and techniques to remove impurities, ensuring that your gases and solvents are of the highest quality. Don't let contaminants compromise the integrity of your work – trust us to provide the best purification services in the industry.

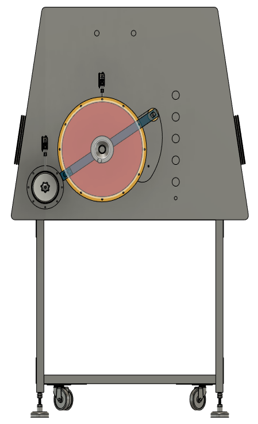

At our company, we understand that every industry and application has unique needs and requirements. That's why we offer custom design services for gloveboxes to ensure that our clients have a solution that meets their specific needs.

Our team of experienced designers and engineers is dedicated to creating innovative and tailored solutions that meet the specific needs of our clients. We have a proven track record of delivering high-quality custom designs that are both functional and aesthetically pleasing.

Whether you have a specific design in mind or need help developing a concept from scratch, we have the expertise and resources to help. Our team will work closely with you to understand your needs and develop a custom design that meets all of your requirements.

Adapt To Your Specifications

Technical Support

Verification Of The Technical Designs

Deliver Enhanced Technical Quality

Unlimited Range Of Options

CAD Engineering And Simulations

Project Management

Service And Validation

Design Consultation

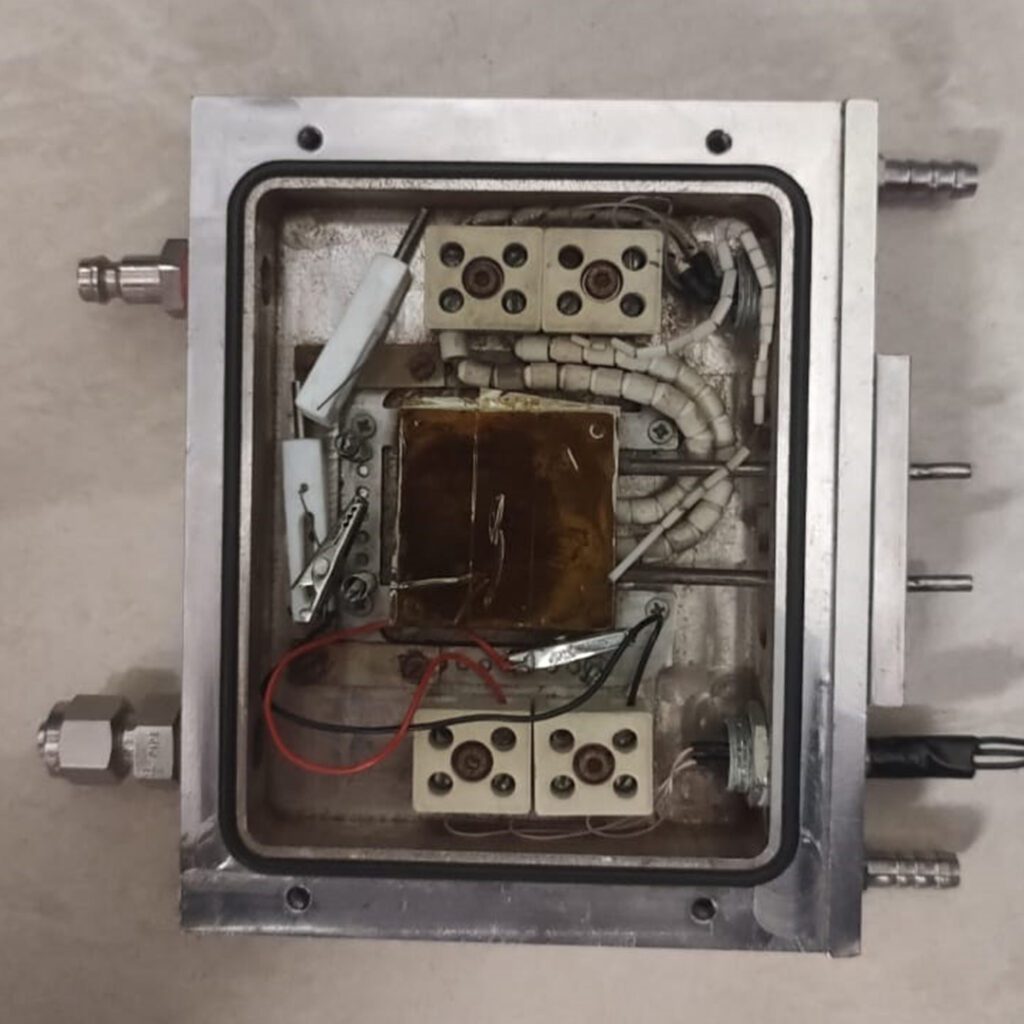

We understand that gloveboxes require ongoing maintenance and repairs to ensure that they are operating at their best. Henceforth, we offer a wide range of spares and accessories to help you keep your glovebox in top condition.

Our team of experienced technicians is dedicated to providing the best possible support and service for our clients. We offer a range of spares and accessories, including custom designs, to meet the specific needs of our clients. We also offer ongoing support and service to ensure that your glovebox is operating at its best.

Sensor and Analyser

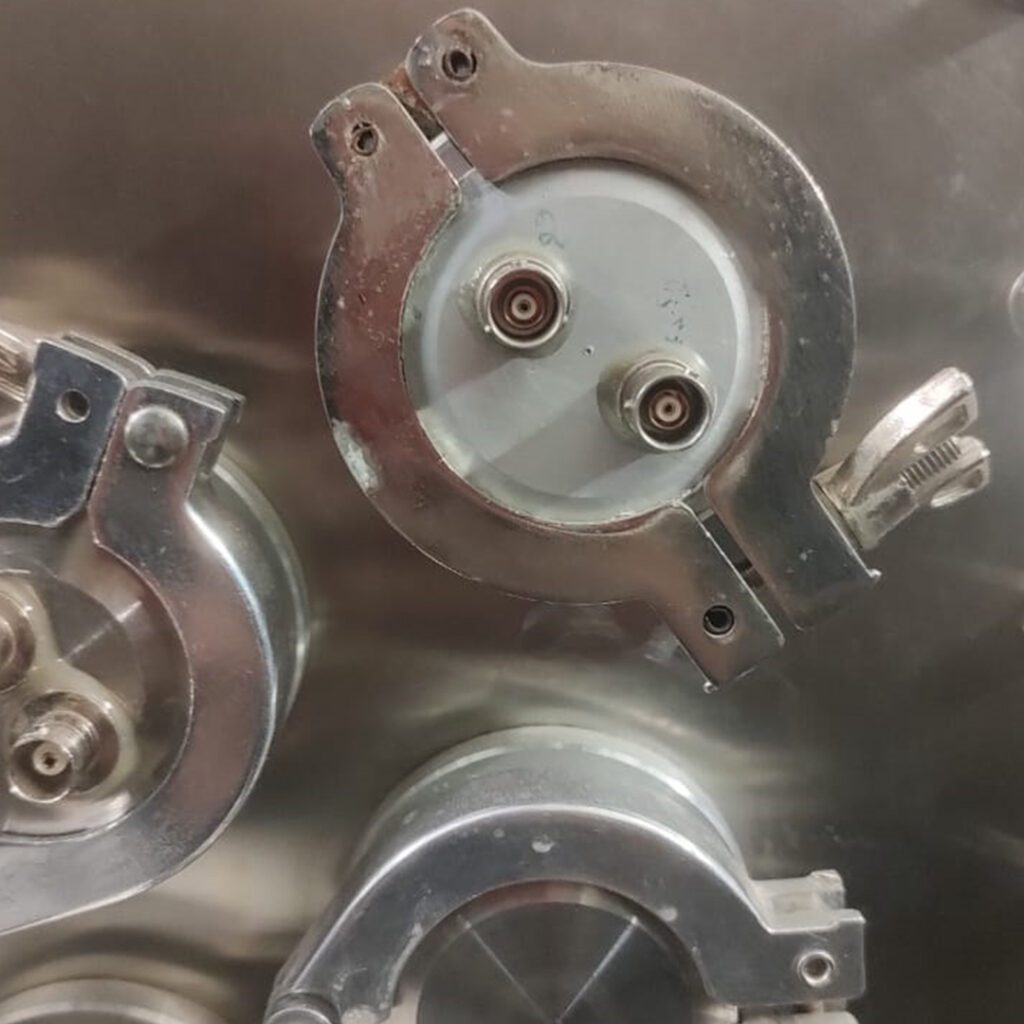

Glove Port

Gloves

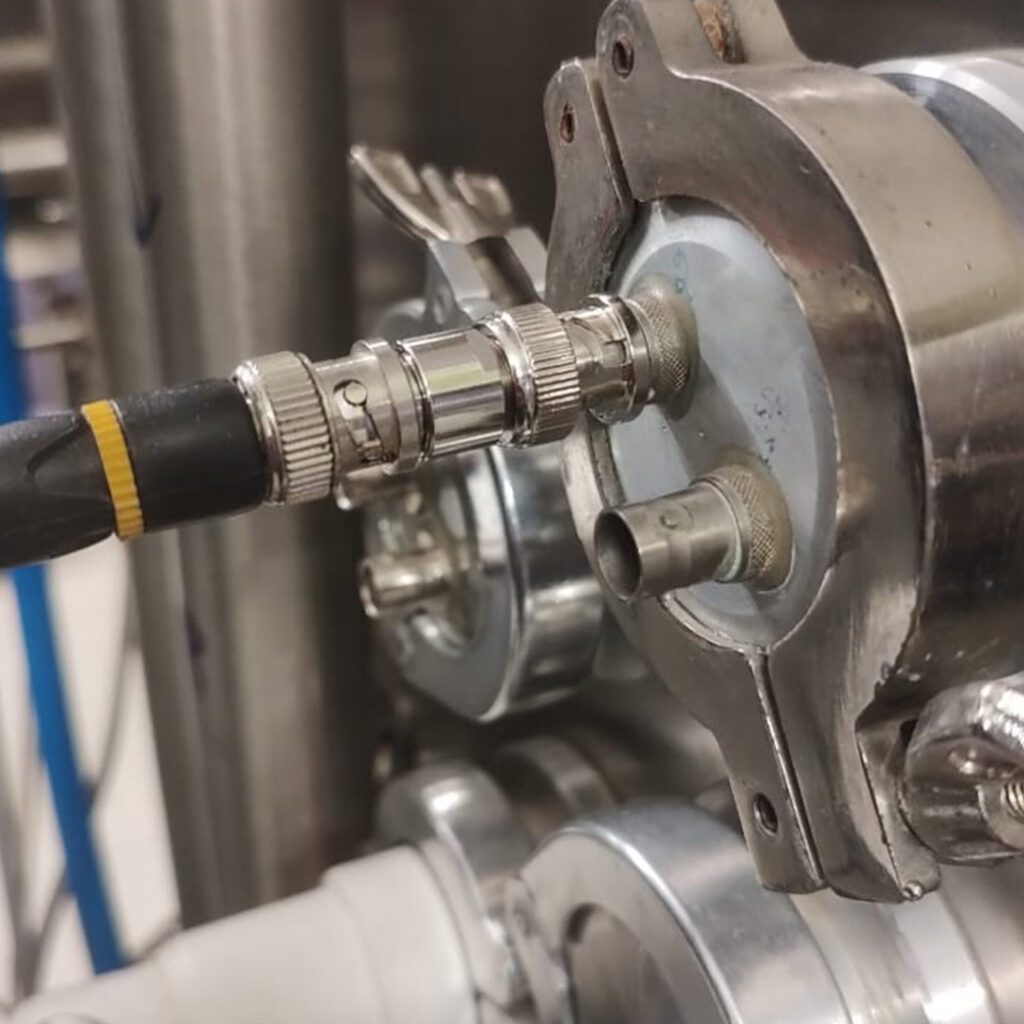

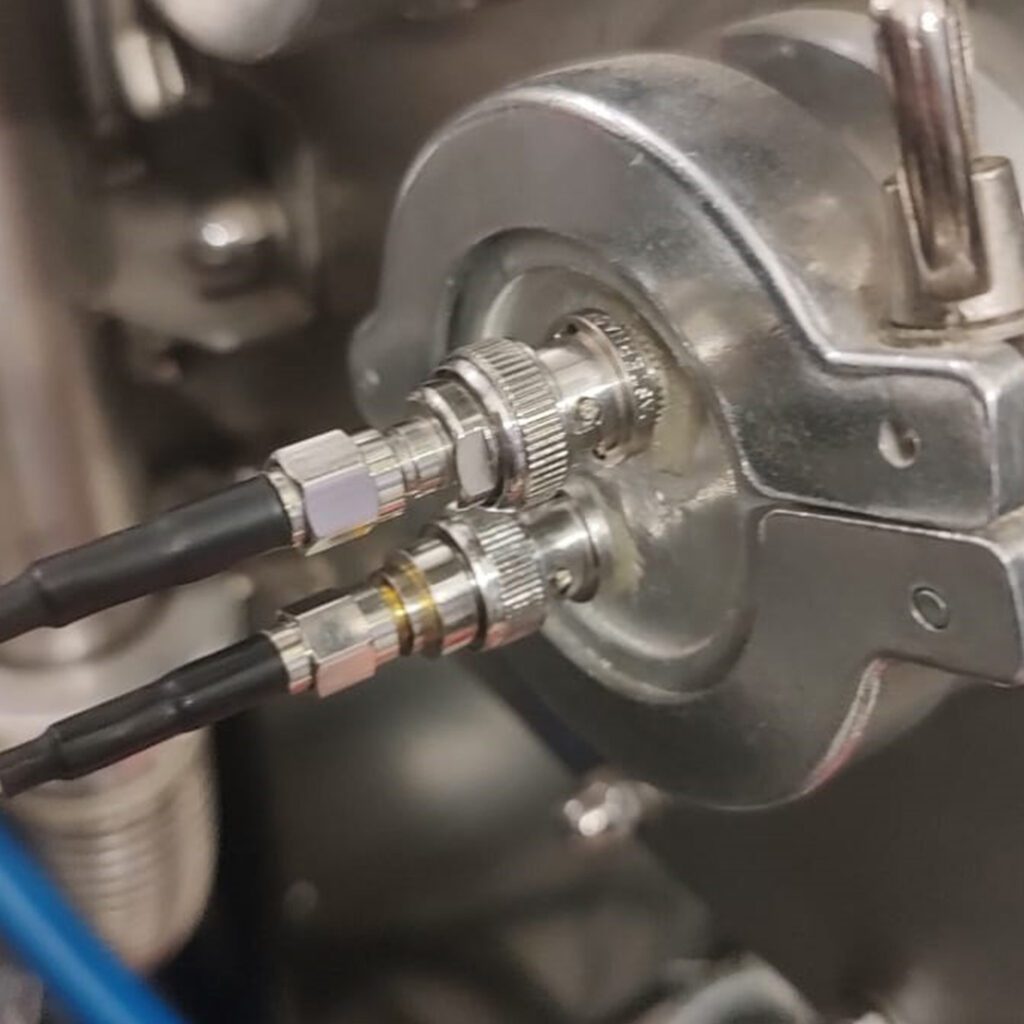

Feedthrough

Vacuum Pump and Parts

Others

Filter Media

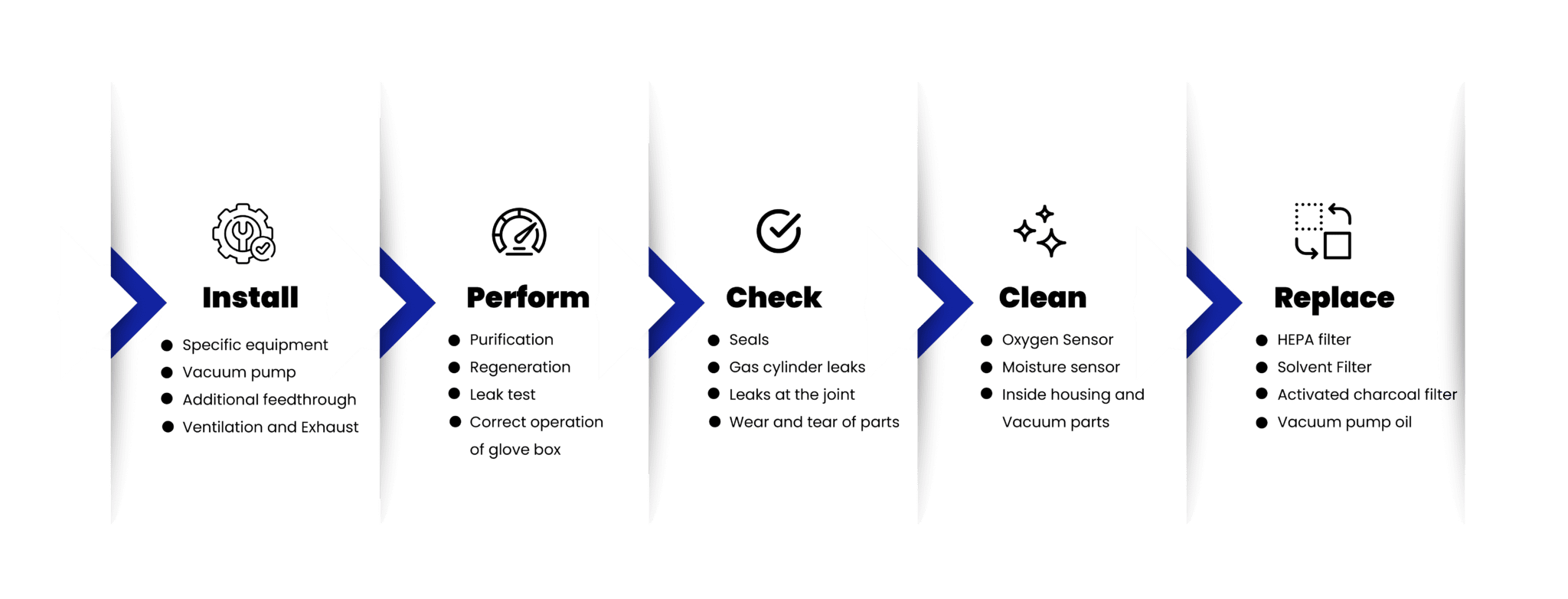

We Are A Company Dedicated To Provide The Highest Quality Service And Training For Gloveboxes In A Variety Of Industries. We Also Have Expertise To Service And Repair Gloveboxes That Is Not Manufactured And Sold By Us. Our Team Of Experienced Technicians Is Trained To Handle All Aspects Of Glovebox Service, Including Installation, Maintenance, Repair, And Decommissioning. We Use Only The Best Tools And Techniques To Ensure That Your Glovebox Is Operating At Its Best.

Whether you need service for your existing glovebox or looking to train your team on its proper use, we have the expertise and resources to help. Contact us today to learn more about our service and training options and to discuss your specific needs.

At Reviun, we pride ourselves on providing top-notch service for our clients. Hence our skilled team are ready and eager to embark on a journey to any corner of the world to care your glove box including accessories, parts and integrated equipment.

Please allow us to exceed your expectations and give your equipment the care it deserves!!!!

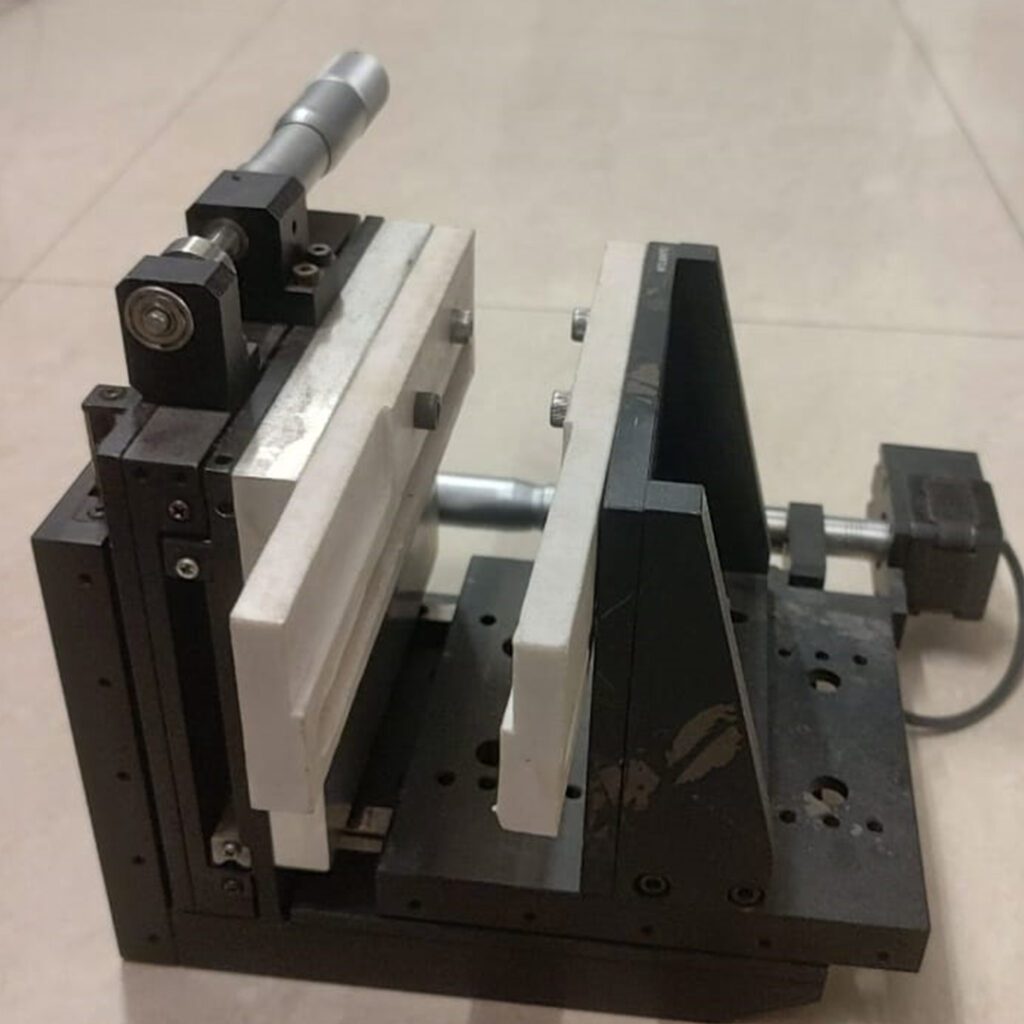

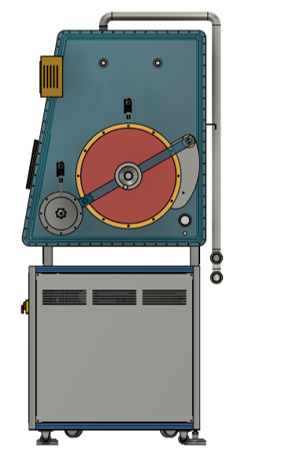

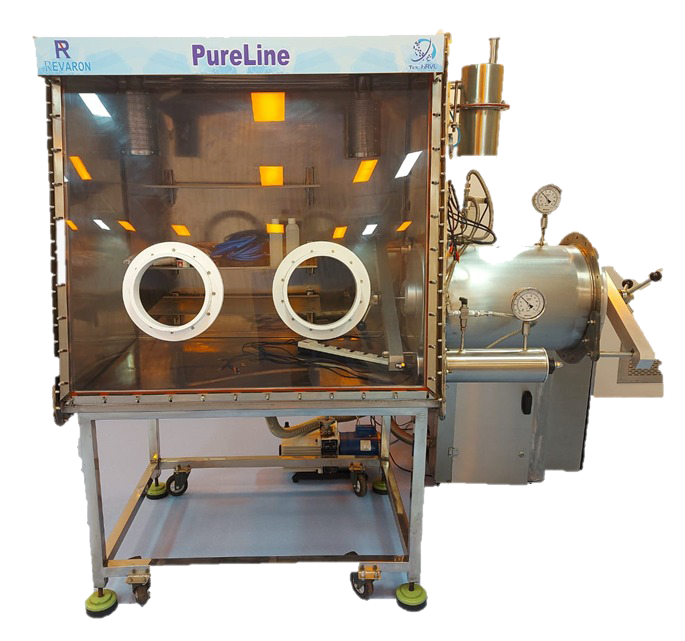

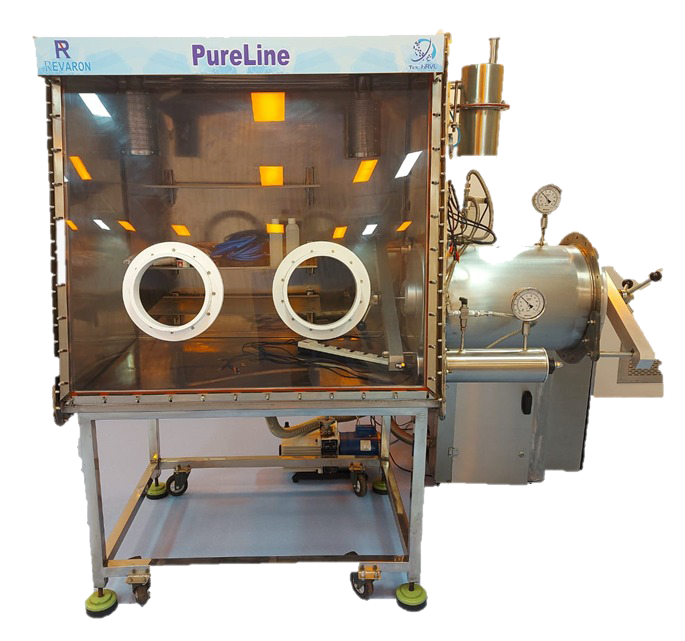

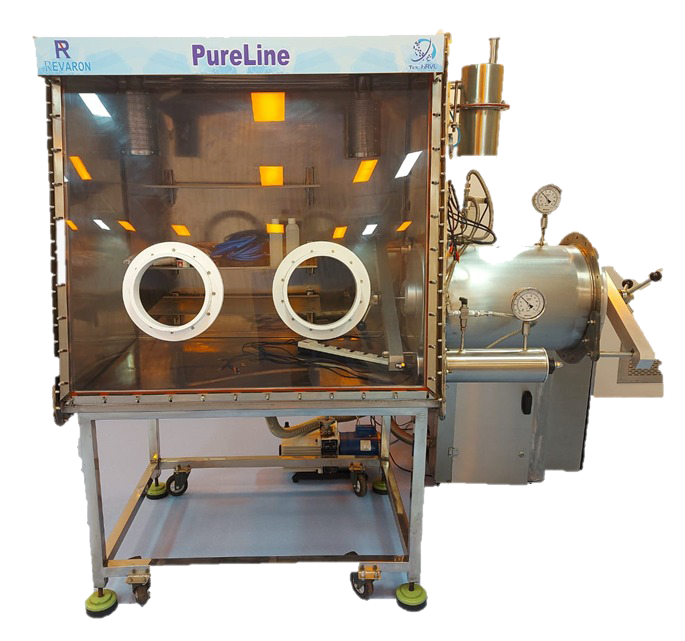

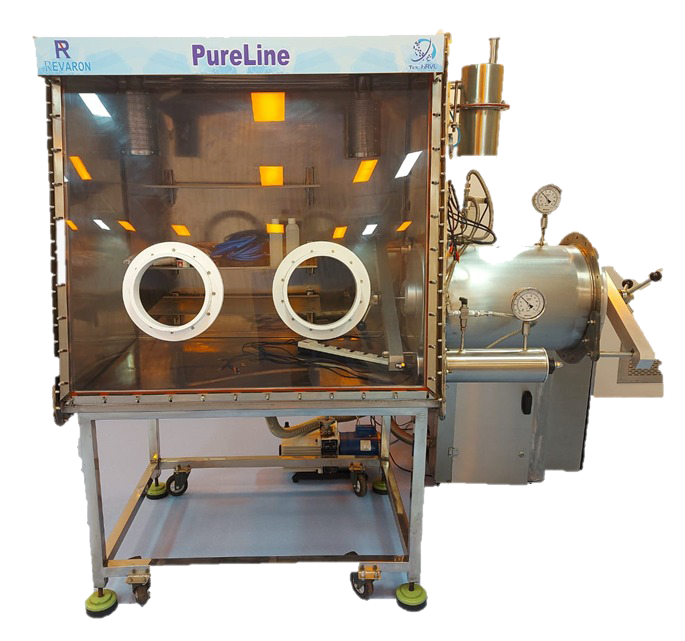

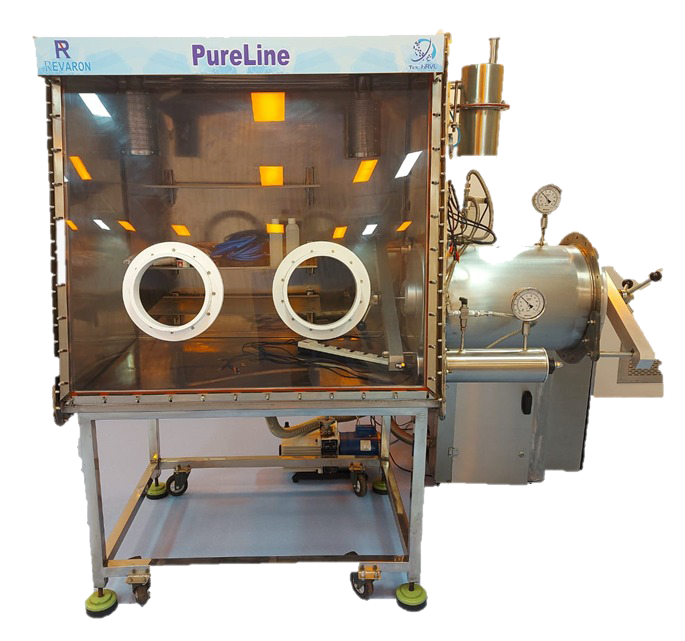

Our Team Of Engineers And Designers Are Dedicated To Creating Innovative Equipment Solutions That Are Tailored To The Specific Needs Of Our Clients. We Offer A Range Of Standard Integrated Equipment Options, Including Custom Designs, To Ensure That Our Clients Have The Right Equipment They Need To Conduct Their Work Safely, Effectively, Efficiently And More Importantly Innovatively !

Adding Process Equipment Inside The Glovebox Should Be Considered Seriously. We Provide Equipment (Few From Third-Party Suppliers) That Is Suitable To Be Used Inside The Glovebox At Positive And Negative Pressures. If You Are In An Industry Or Academia That Uses Gloveboxes And Are In Need Of Integrated Equipment Solutions, Don't Hesitate To Contact Us. Few Are Listed Below And We Are Happy To Consider Other Requests That Are Not Listed.

Solvent Purifier

Sol-Gel Coating Equipment

CVD

PVD ( Thermal, Sputtering, E-Beam)

Robotic Automation

Encapsulation

Freezer (Upto -5 C)

Deep Freezer (Upto -80 C)

Electrolyte Dispensing And Filling

Hot Plate

Spin Coaters

Oven (Upto 200 C)

Incubator

Cold Well

UV And Ozone Cleaner

Solar Simulator

Electrical Workstation

Electrochemical Workstation